Product introduction

Product consultation →

Product consultation →

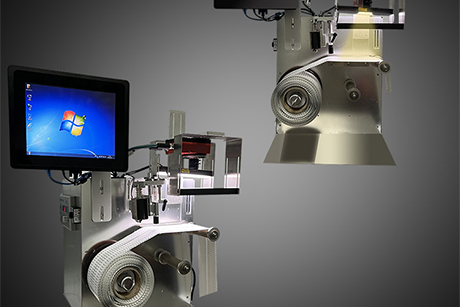

A QR code defect detection system for precise, efficient, and fast detection

Product Details

System Introduction:

The QR code defect online detection system is used to detect common defects such as broken edges, stains, mosquitoes, holes, and impurities on the surface of various code marked products during the production process. The machine vision system can timely detect the defect information on the product surface during the production process, reflect the defect information on the production line surface in real time, and perform defect classification processing, completely replacing manual visual defect detection. Greatly saving production costs, improving production efficiency, and ensuring the quality of code labels.

System advantages:

◆ Detection speed up to 0.5S

◆ Detection accuracy of 99%, reducing errors caused by manual detection

◆ 24-hour uninterrupted work to improve production efficiency

◆ Avoid unnecessary losses and save resources

◆ Automatically generate data statistics tables

◆ Output product appearance mechanism according to level standards

◆ Machines replace labor, saving labor costs

◆ Adopting high-speed high-definition industrial cameras, capturing details clearly and ensuring stable detection

◆ Data based quality control

Customized solutions

◆ Solve the problem of difficulty in distinguishing millimeters by the human eye

Application scenario:

The machine vision defect detection system has a wide range of applications, mainly used for detecting product appearance defects, such as QR codes, OCR characters, metal surfaces, film surfaces, glass surfaces, paper surfaces, non-woven fabric surfaces, electronic component surfaces, aluminum-plastic plate surfaces, and some composite materials that have strict requirements and clear indicators for appearance.

Back to list

Back to list